Stacked Rapid Sand Filter

Design information for the AguaClara Stacked Rapid Sand Filter (StaRS) is available in the Open Stacked Rapid Sand Filter Design chapter of The Physics of Water Treatment Design

Purpose and Description

The StaRS filter removes particles and pathogens from the clarified water. The StaRS filter was designed to eliminate the need for pumps and storage tanks that are normally required for backwashing rapid sand filters. The StaRS filter has the same flow rate in filtration mode and in backwash mode. An elegant filter hydraulic design enables switching from filtration mode to backwash mode without using any large diameter valves. Backwash is accomplished using clarified water and that increases the efficiency of water production by the AguaClara plant.

The hydraulic controls are on the main plant floor and are open so that the plant operators can readily observe head loss through the filter as well as the clarity of the clarified and filtered water.

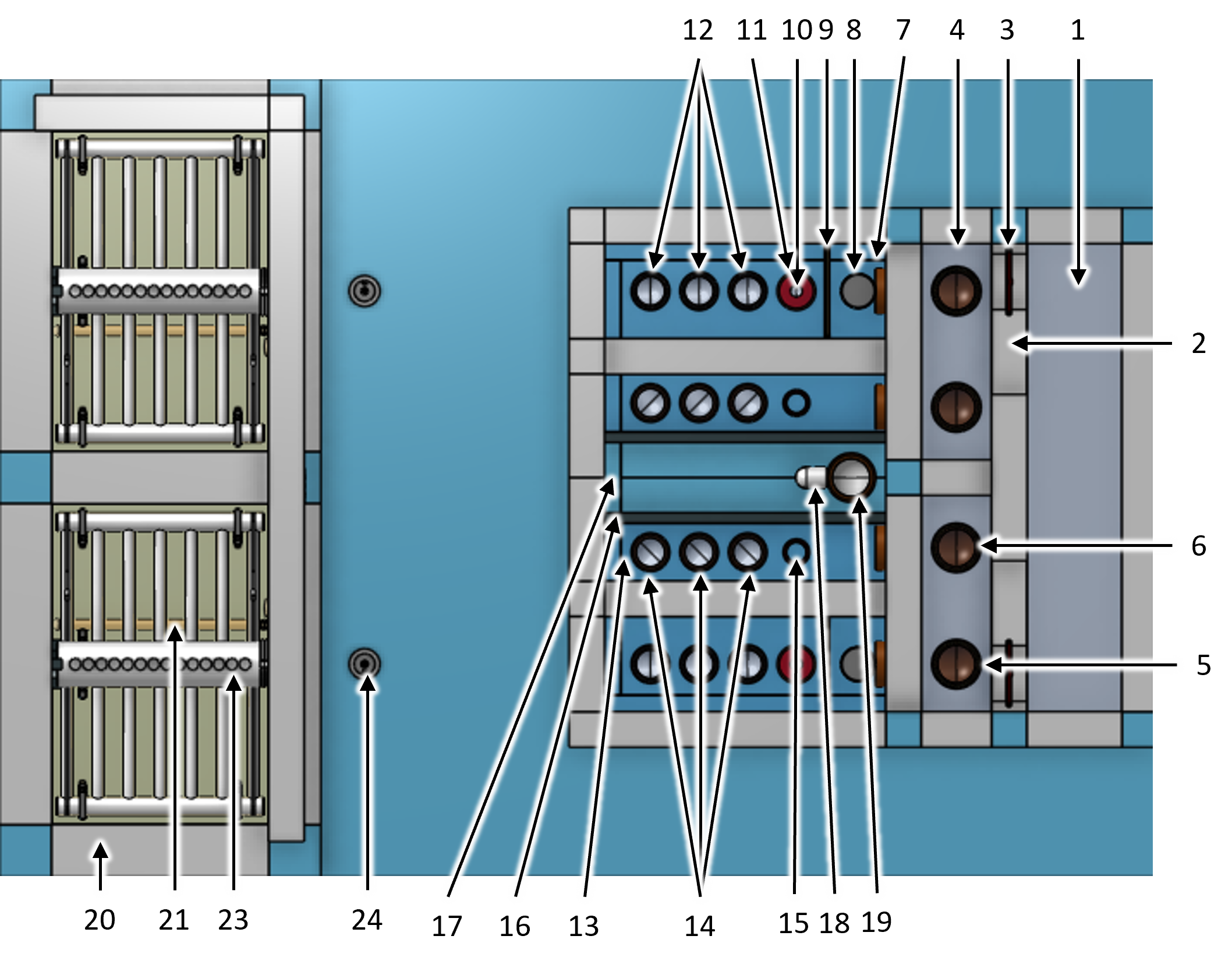

The plan view of the filter (Fig. 22) shows the filter chambers and the hydraulic controls separated by a walkway.

Fig. 22 Filter top view showing filter hydraulic controls and filter chambers for a 2 filter chamber design.

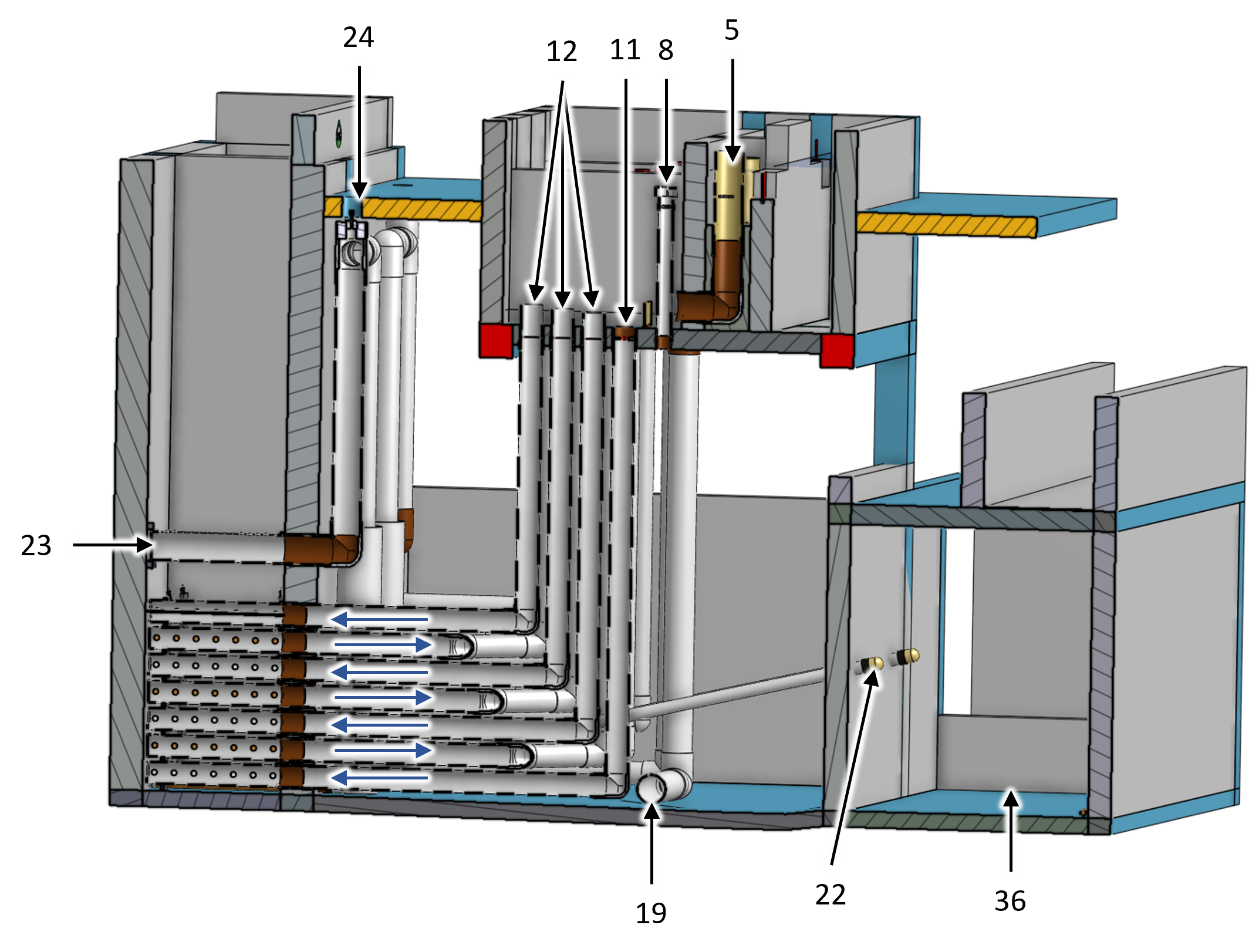

The isometric side view of the filter (Fig. 23) with the filter wall and backwash tank wall removed shows the filter internal piping as well as the pipes that connect the filter controls to the filter chamber.

Fig. 23 Filter isometric view showing filter hydraulic controls and filter chambers for a 2 filter chamber design.

The section view cutting through the center of the first filter chamber (Fig. 24) shows that the center of the filter controls inlet tank is aligned with the center of the filter chamber. Thus the four inlet pipes have a straight path into the filter chamber. The outlet pipes have a 45° elbow to account for the offset to the filter controls outlet tank.

Fig. 24 Filter left section isometric view showing how the inlet tank, filter chamber, and siphon pipe are all aligned. The different heights of the inlet pipe stubs in the inlet tank are also shown.

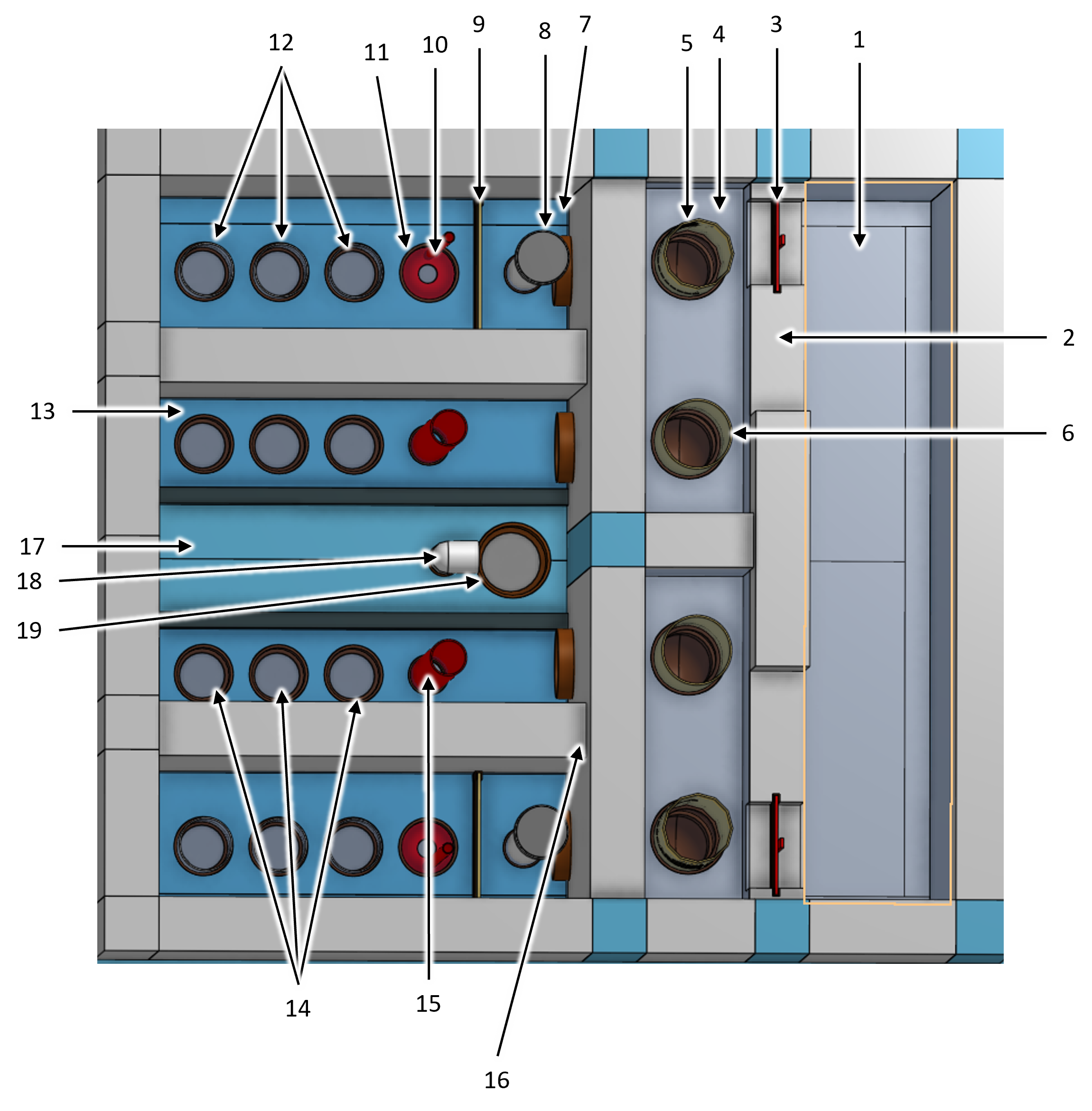

The filter controls (Fig. 25) provide the operator with a method to rapidly confirm filter operation. The filter controls come in pairs when there is more than one filter chamber so they can share the finished water tank.

Fig. 25 Filter controls top isometric view.

Water flows from right to left from the inlet channel, over the wide weir to the bypass channel. During normal operation the water enters the LFOM and flows into the filter controls inlet tank (Fig. 26). If there is a need to bypass a filter the LFOM and bypass pipe stubs are simply swapped. During backwash the gate can be removed so that the filter receives the design flow rate. The filter controls inlet tank has an overflow that dumps water to the backwash tank when the head loss through the filter exceeds the maximum design value. The bubble weir raises bubbles to minimize their entry into the filter inlets. The short pipe stubs in the filter inlets ensure that the water all enters the backwash inlet during backwash. The different heights of the pipe stubs causes the filter sand to fluidize gradually starting from the sand near the top of the filter and progressing deeper as more of the water is forced into the bottom inlets.

Fig. 26 Filter controls inlet tank. The backwash orifice plate is in place for filtration mode.

Water exits the filter chamber through three outlet pipes and then enters the filter controls outlet tank (Fig. 27). After backwash the red pipe stub can be removed as shown in the foreground outlet tank to enable filtering to waste. When not filtering to waste the water flows over the filtered water weir into the finished water tank and finally into the finished water pipe.

Fig. 27 Filter controls outlet tank section showing water levels. The outlet tank in the foreground has the pipe stub that enables filter to waste removed. The outlet tank in the background has the pipe stub in place to prevent filtering to waste.

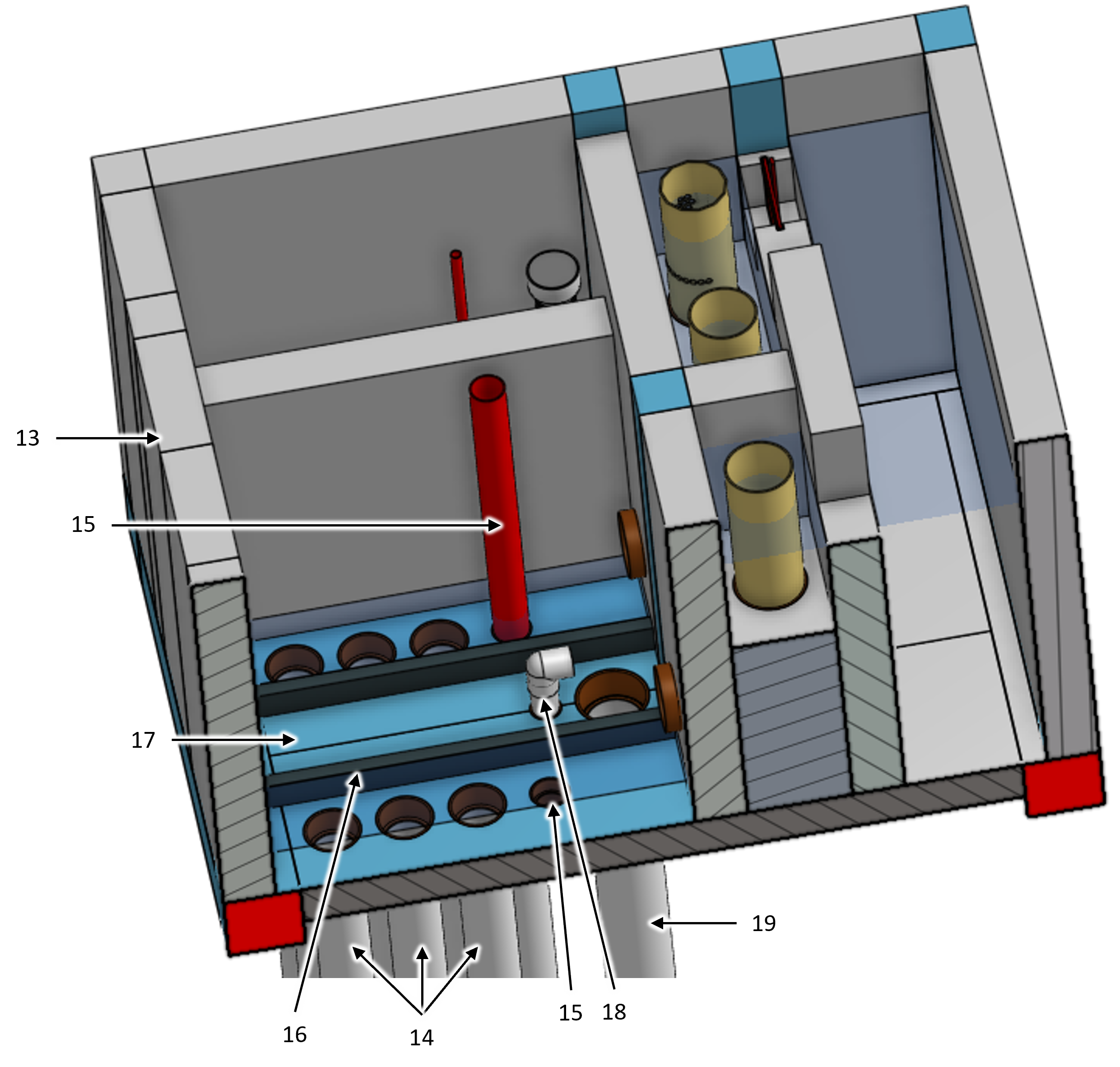

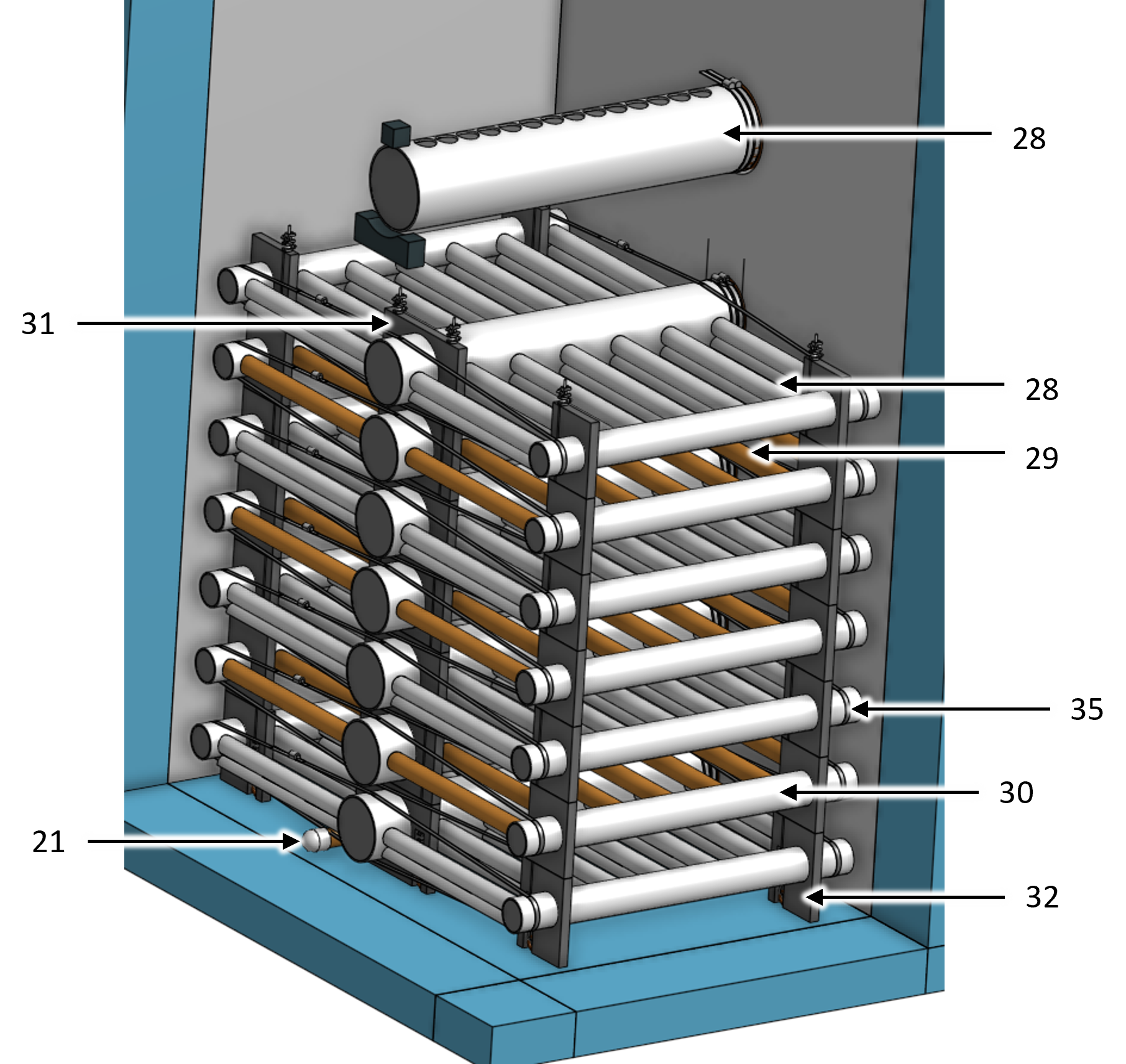

The filter chamber internal piping (Fig. 28) serves to divide the sand bed into 6 layers. The with flow through each layer alternates direction with the bottom layer flowing upward and the next layer flowing downward.

Fig. 28 Filter internal piping showing how the modules, siphon, and filter drain are placed in the filter chamber.

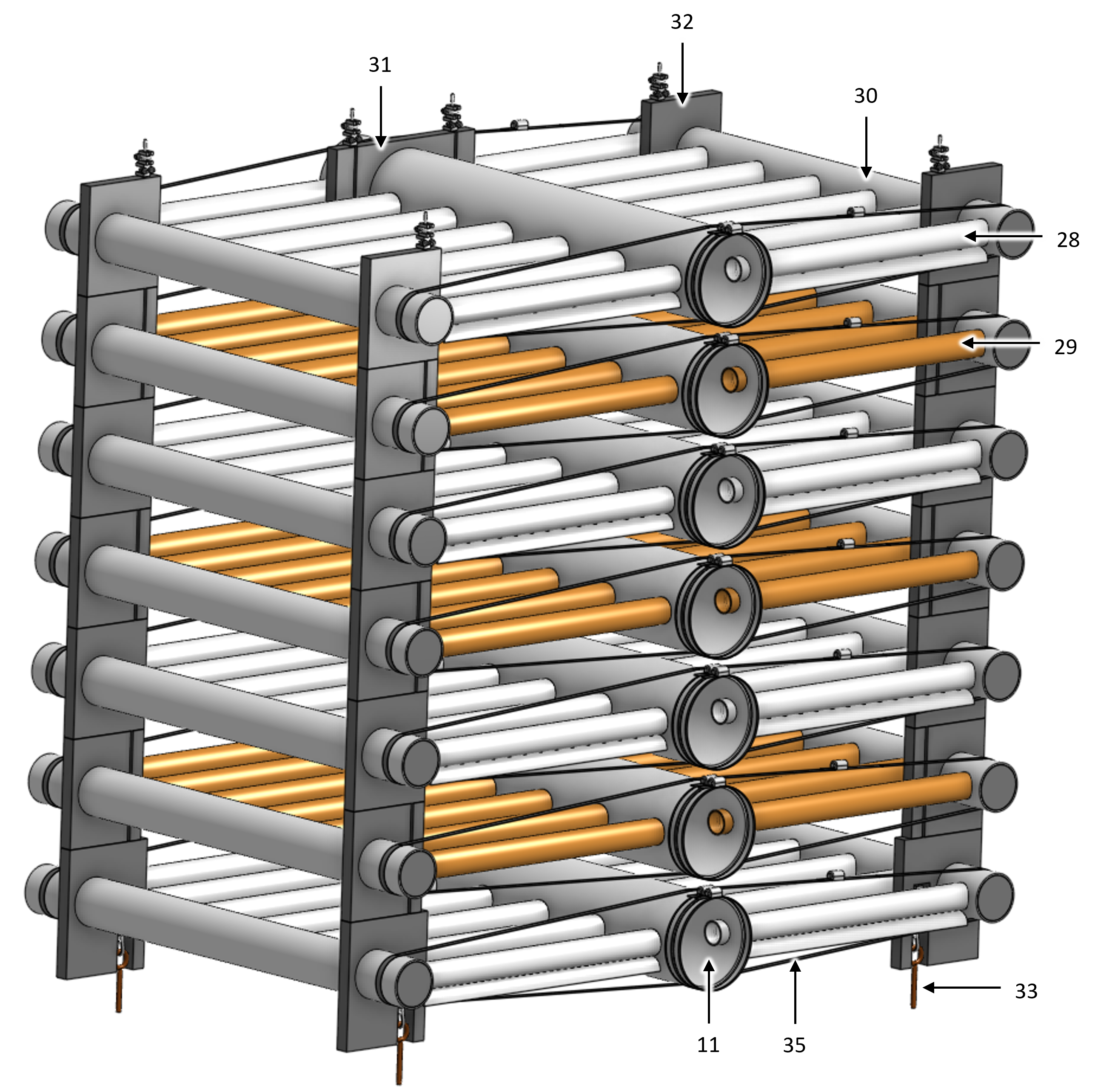

The filter internal piping consists of 7 modules (Fig. 29) for easy assembly in the filter chamber. Each module stacks on top of the module below. The tie-down cable ensures that the modules can not shift relative to each other and it also clamps the entire set of modules in place to prevent uplift during backwash initiation.

Fig. 29 Filter internal piping modules showing how the modules stack, are prevented from lifting by cables anchored to the concrete slab, and attach to the pipes embedded in the filter chamber wall.

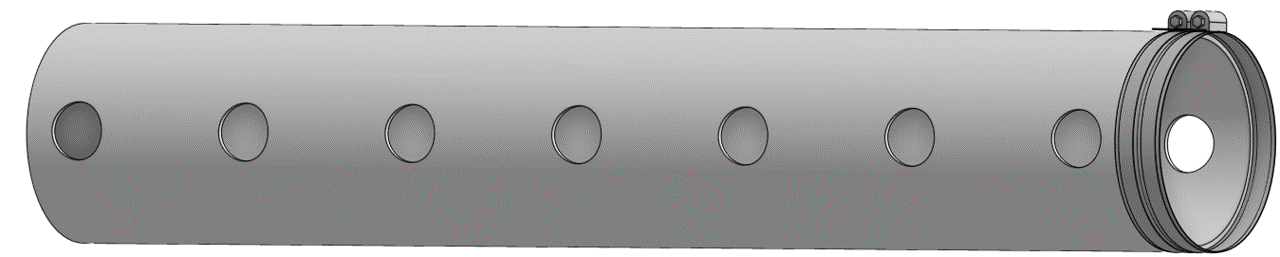

The main trunk pipe (Fig. 30) in each module is connected to the embedded pipe that connects to either the filter control inlet tank or filter control outlet tank. The pipe connections is a stainless steel band that is then held in place with two hose clamps. The ports for the branches slightly smaller than the outside diameter of the branches so that the molded end of the branches can only be inserted a fixed distance into the trunk.

Fig. 30 Filter inlet trunk isometric showing the ports for the branches and the band clamp system that attaches to a pipe embedded in the filter chamber wall.

The 200 mm spacing of the trunks and receptors is set by the spacers (Fig. 31). The cable grooves alternate sides on the spacers so that the cables prevent the spacers from moving. The spacers are attached to the trunks and receptors.

Fig. 31 Filter trunk spacer front and top views.

The receptors (Fig. 32) are symmetrical and have PVC disks that plug both ends. The compact design of the PVC disks enables the first and last branches to be relatively close to the filter chamber walls.

Fig. 32 Filter inlet receptor isometric showing the end plug and the ports for the branches.

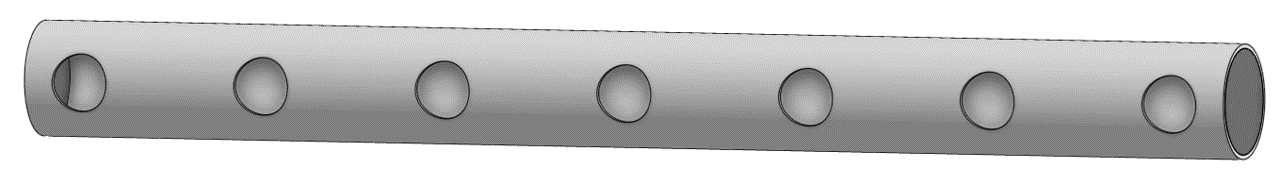

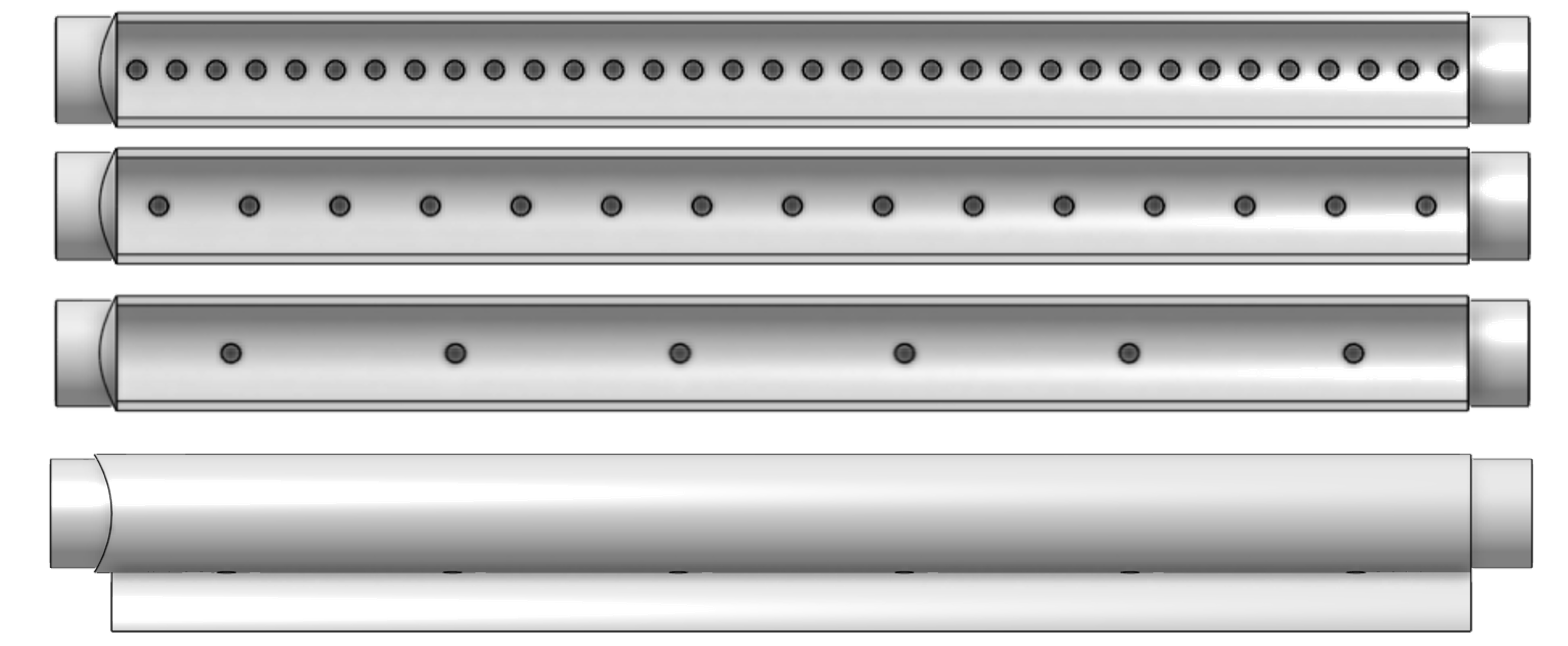

There are three types of inlet branches (Fig. 33). The bottom backwash branches have the most orifices to be able to handle the high backwash flow rate. This results in the backwash branches having insufficient head loss during normal filtration. To accommodate the low backwash branch head loss an orifice plate is added to the backwash inlet during filtration. The middle two inlet modules both deliver clarified water to two sand layers and thus should have at least twice as many orifices as the top inlet branches. The middle inlets need even more orifices to account for the added head loss in the inner trunks given that the inner trunks have double the flow rate of the top and bottom trunks during filtration.

Fig. 33 Filter inlet branches showing the bottom view (top to bottom) of the backwash branches, middle two inlet branches, top inlet branches, and side view of an inlet branch. The ends of the branches are molded to create a sand tight connection with the trunk and receptor pipes.

Filter Keys

Key |

Name |

Purpose |

|---|---|---|

1 |

inlet channel |

receives the water from 1 clarified water pipe coming from the clarifier and distributes the water to 1 filter chambers |

2 |

wide weir |

uses head loss to divide the flow equally between the filter chambers |

3 |

removable gate |

can be removed to provide full design flow to a filter during backwash |

4 |

bypass channel |

provides option to bypass the filter by swapping the LFOM and bypass pipes |

5 |

LFOM |

measures the flow rate into the filter |

6 |

bypass pipe |

pipe stub that can be swapped with the lfom to bypass the filter |

Key |

Name |

Purpose |

|---|---|---|

7 |

inlet tank |

distributes the clarified water to the 4 filter inlets |

8 |

overflow |

automatically diverts clarified water to the pipe gallery when the filter head loss exceeds the maximum design value |

9 |

bubble weir |

lifts bubbles to prevent them from entering the inlets to the filter |

10 |

backwash orifice plate |

adds head loss to filter inlet 1 during filtration so that it has the same head loss as the other inlets. Removed during backwash. |

11 |

backwash trunk |

deliver water from the inlet tank to the filter chamber during filtration and during backwash |

12 |

inlet trunks |

deliver water from the inlet tank to the filter chamber during filtration |

Key |

Name |

Purpose |

|---|---|---|

13 |

outlet tank |

collects filtered water from the 3 outlet trunks |

14 |

outlet trunks |

deliver water from the filter chamber to the outlet tank during filtration |

15 |

filter to waste |

dumps filtered water to the pipe gallery. Remove the pipe stub after backwash to waste filtered water that doesn’t meet treatment standards. |

16 |

filtered water weir |

enables filtering to waste |

17 |

finished water tank |

adds chlorine to the filtered water and delivers the water to the finished water pipe |

18 |

chlorination conduit |

provides a path for a chlorination tube to drip into the water exiting from one of the filters |

19 |

finished water pipe |

delivers the finished water to the community water storage tank |

Key |

Name |

Purpose |

|---|---|---|

20 |

filter chamber |

contains the filter internal piping and filtered sand |

21 |

filter chamber drain |

drains water for maintenance operations |

22 |

sand dump pipe |

empties the sand from the filter |

23 |

siphon pipe |

discharges backwash to the pipe gallery |

24 |

siphon air valve |

controls the siphon and switches the filter from filtration to backwash and back again |

25 |

siphon water seal |

prevents the water from exiting the siphon at the end of the backwash |

26 |

sand |

provides the filter media and pore structure for capture of flocs and particles |

Key |

Name |

Purpose |

|---|---|---|

27 |

band clamps |

attach the trunks to the pipes that are embedded in the filter tank chamber wall |

28 |

winged branch pipes |

injects clarified water into the sand bed |

29 |

slotted branch pipes |

extracts filtered water from the sand bed |

30 |

receptor pipes |

terminate and support the winged and slotted branch pipes |

31 |

trunk spacer |

supports the end of the trunks |

32 |

receptor spacer |

supports the receptor spacers |

33 |

anchor bolts |

connects the cable to the concrete slab |

34 |

cable |

prevents the internal pipe modules from lifting during backwash initation |

35 |

hose clamp |

tightens all of the connections between branches, receptors, and trunks to prevent sand leaks |

Key |

Name |

Purpose |

|---|---|---|

36 |

sand tank |

receives, drains, and temporarily stores filter sand during filter maintenance operations |

37 |

sand tank overflow weir |

excess water discharges over this weir |

38 |

slotted sand drain |

discharges water from the sand |

39 |

sand tank overflow drain |

discharges overflow water from the sand tank |

40 |

pipe gallery and filter backwash water tank |

option to use this tank to enable recycle of backwash water |

41 |

pipe gallery drain |

discharges water from the pipe gallery |

Filter Design Parameters

Key |

Name |

Value |

|---|---|---|

1 |

inlet channel |

|

water depth |

1.23 m |

|

width |

460 mm |

|

2 |

wide weir |

|

height |

400 mm |

|

width |

580 mm |

|

maximum head loss |

50 mm |

|

3 |

removable gate |

|

height |

200 mm |

|

width |

220 mm |

|

4 |

bypass channel |

|

width |

280 mm |

|

5 |

LFOM |

|

nominal diameter |

6 inch |

|

SDR |

41 |

|

number of rows of orifices |

10 |

|

maximum flow rate |

12 L/s |

|

head loss at maximum flow |

200 mm |

|

diameter of orifices |

19.1 mm |

|

space between orifices measured on the outside of the pipe |

3 mm |

|

orifices in each row starting from bottom row |

[ 15, 4, 5, 3, 3, 4, 2, 2, 3, 2] |

|

elevation of each row from zero flow datum |

[ 9.53 mm, 29.6 mm, 49.7 mm, 69.8 mm, 89.9 mm, 110 mm, 130 mm, 150 mm, 170 mm, 190 mm] |

|

6 |

bypass pipe |

|

nominal diameter |

6 inch |

|

SDR |

41 |

Key |

Name |

Value |

|---|---|---|

7 |

filter inlet tank |

|

length |

1.44 m |

|

width |

460 mm |

|

8 |

overflow |

|

nominal diameter |

4 inch |

|

SDR |

26 |

|

maximum water depth |

980 mm |

|

9 |

bubble weir |

|

height |

190 mm |

|

width |

460 mm |

|

10 |

backwash orifice plate |

|

orifice diameter |

60 mm |

|

11 |

backwash trunk |

|

nominal diameter |

6 inch |

|

SDR |

41 |

|

maximum head loss during filtration |

34.6 mm |

|

maximum velocity during filtration |

99.4 mm/s |

|

maximum head loss during backwash |

156 mm |

|

maximum velocity during filtration |

596 mm/s |

|

12 |

inlet trunks |

|

nominal diameter |

6 inch |

|

SDR |

41 |

|

maximum head loss during filtration |

34.6 mm |

|

inner trunks maximum velocity during filtration |

199 mm/s |

|

inlet 1 (backwash) pipe stub height |

none |

|

inlet 2 pipe stub height above the slab |

100 mm |

|

inlet 3 pipe stub height above the slab |

1.25 * 100 mm |

|

inlet 4 pipe stub height above the slab |

1.5 * 100 mm |

Key |

Name |

Value |

|---|---|---|

13 |

outlet tank |

|

length |

460 mm |

|

width |

280 mm |

|

14 |

outlet trunks |

|

nominal diameter |

6 inch |

|

SDR |

41 inch |

|

15 |

filter to waste |

|

nominal diameter |

4 inch |

|

SDR |

26 |

|

16 |

filtered water weir |

|

height |

100 mm |

|

maximum head loss |

58.2 mm |

|

17 |

finished water tank |

|

half width |

115 mm |

|

18 |

chlorination conduit |

|

nominal diameter |

3 inch |

|

SDR |

26 |

|

19 |

finished water pipe |

|

nominal diameter |

4 inch |

|

SDR |

26 |

Key |

Name |

Value |

|---|---|---|

20 |

filter chamber |

|

number of filter chambers |

1 |

|

number of spare filter chambers |

0 |

|

length |

900 mm |

|

width |

1.44 m |

|

height |

4.61 m |

|

number of stacked filters |

6 |

|

height of each layer |

200 mm |

|

21 |

filter chamber drain |

|

nominal diameter |

1.5 inch |

|

22 |

sand dump pipe |

|

nominal diameter |

2 inch |

|

SDR |

26 |

|

Discharge height |

1 m |

|

23 |

siphon pipe |

|

nominal diameter |

6 inch |

|

SDR |

41 |

|

initial flow rate at beginning of backwash |

61.2 L/s |

|

head loss at filter chamber design flow |

95.4 mm |

|

number of orifices |

15 |

|

orifice diameter |

42.4 mm |

|

orifice center to center spacing |

49.9 mm |

|

24 |

siphon air valve |

|

nominal diameter siphon control air vent valve |

0.5 |

|

25 |

siphon water seal |

|

nominal diameter siphon control air vent valve |

10 |

|

head loss over the weir of the pipe |

39.7 mm |

|

optional concrete fill height |

1.66 m |

|

26 |

sand |

|

depth |

1.34 m |

|

fluidized depth |

1.25 m |

|

density |

2.65 kg/L |

|

porosity |

0.4 |

|

effective size |

500 μm |

|

clean bed headloss at 5 °C |

75.4 mm |

|

clean bed headloss at 25 °C |

45.4 mm |

|

head loss to fluidize sand |

1.24 m |

|

bulk volume of sand per filter chamber (not accounting for volume of internal pipes) |

1.73 kL |

|

mass of sand per filter chamber (not accounting for volume of internal pipes) |

1.84 Mg |

Key |

Name |

Value |

|---|---|---|

27 |

band clamps |

|

band width |

40 mm |

|

band thickness |

200 μm |

|

28 |

winged branch pipes |

|

nominal diameter |

1.5 inch |

|

SDR |

12.3 |

|

29 |

slotted branch pipes |

|

nominal diameter |

1.5 inch |

|

SDR |

12.3 |

|

length (not including molded ends) |

502 mm |

|

30 |

receptor pipes |

|

nominal diameter |

3 inch |

|

SDR |

26 |

|

31 |

trunk spacer |

|

thickness |

25.4 mm |

|

32 |

receptor spacer |

|

thickness |

25.4 mm |

|

33 |

anchor bolts |

|

maximum force on anchor bolts |

1750 { kilogram : 1 , meter : 1 , second : -2 } |

|

34 |

cable |

|

diameter |

4.76 mm |

|

maximum force on trunk cables |

1750 { kilogram : 1 , meter : 1 , second : -2 } |

|

35 |

hose clamp |

Key |

Name |

Purpose |

|---|---|---|

36 |

sand tank |

|

minimum volume |

1.73 kL |

|

length |

2.83 m |

|

width |

1.72 m |

|

37 |

sand tank overflow weir |

|

height |

610 mm |

|

38 |

slotted sand drain |

|

nominal diameter |

1.5 inch |

|

39 |

sand tank overflow drain |

|

nominal diameter |

4 inch |

|

40 |

pipe gallery and filter backwash water tank |

|

maximum depth |

1.88 m |

|

volume |

20.7 kL |

|

maximum number of backwash cycles |

20.7 kL |

|

41 |

pipe gallery drain |

|

nominal diameter |

4 inch |